A QMS is a formalized system that documents policies, processes, and responsibilities for achieving quality objectives and compliance with customer and regulatory requirements. An effective QMS delivers compliance, product and service quality, and drives operational excellence through measurable, risk-based, and continuously improving processes.

An effective QMS consistently delivers planned quality outcomes, ensures compliance with applicable requirements (ISO 13485, ISO 9001, FDA 21 CFR Part 820), and supports risk-based decision-making throughout the product lifecycle. An effective QMS also drives operational effectiveness, ensures data integrity, and measures QMS performance using pre-defined Key Performance Indicators (KPIs).

QMS effectiveness can be measured both at the system-level (e.g., audit outcomes, CAPA cycle time) and process-level (e.g., supplier defect rates, training effectiveness). These quality metrics include internal and external audit results, CAPA closure time, risk register status, process capability indices (Cp, Cpk, Ppk), and document control performance, among others. These metrics help organizations evaluate the degree of control and compliance, and the effectiveness of continuous improvement efforts.

Improving QMS effectiveness requires leadership commitment, a strong culture of employee engagement, risk-based thinking, and periodic QMS assessments.

A QMS assessment is a structured evaluation of how effectively a quality management system is implemented and maintained. It helps identify gaps, ensure compliance, and guide continuous improvement.

Key measures of QMS effectiveness include internal and external audits, non-conformance and CAPA metrics, process performance indicators (yield, defect rates), document control performance, and effectiveness of risk mitigation actions tracked in the risk register. QMS assessments should also evaluate the organization’s approach to continuous improvement. This includes conducting continual improvement projects using Six Sigma or Kaizen methodologies and establishing defined process KPIs to monitor and enhance each QMS process.

SimplerQMS provides a cloud-based QMS software platform for life science companies, supporting compliance with ISO 13485:2016, ISO 9001, FDA 21 CFR Part 820, and EU MDR/IVDR requirements, and applicable pharmaceutical GMP regulations such as FDA 21 CFR Part 211 and EU GMP.

What Is an Effective QMS?

An effective QMS consists of clearly defined, implemented, and controlled processes. This also includes validated processes where required, such as sterilization. An effective QMS enables an organization to consistently ensure product safety, quality, and regulatory conformity throughout the product lifecycle. It ensures documented compliance with applicable requirements such as ISO 13485:2016, FDA 21 CFR Part 820, EU MDR 2017/745, IVDR 2017/746, ISO 9001, ICH Q10 among others. It demonstrates the ability to maintain process control, mitigate regulatory and product-related risks, and drive continuous quality improvement through measurable and auditable performance indicators.

QMS effectiveness can vary depending on applicable regulatory frameworks, the type of product or service, organizational scale, and product lifecycle phase. For example, in the medical device sector, QMS requirements for high-risk Class III implantable devices are more stringent than for low-risk Class I devices. Class III devices typically require stringent design validation, clinical evaluation, and post-market surveillance controls, whereas low-risk Class I devices are subject to more limited oversight. Therefore, quality management system effectiveness must be evaluated based on the purpose of the QMS and the type of product or service it supports.

QMS effectiveness is evaluated both at the system level and at the individual process level. System-level performance is assessed using indicators such as audit closure rates, frequency of repeat deviations, Corrective and Preventive Action (CAPA) effectiveness metrics, product nonconformance trends, and regulatory inspection outcomes. Process-level indicators include the timeliness and completeness of document control activities, supplier qualification cycle times, and adherence to CAPA implementation timelines.

These quality metrics must be traceable to quality objectives and documented in management review inputs. For example, ISO 13485 Clause 5.6 requires management to review the QMS regularly to ensure regulatory compliance, product quality, and prevention of recurring issues. An effective QMS also demonstrates proactive mitigation of quality risks, data-driven continuous improvement, and integration of quality planning into operational processes.

Conversely, an ineffective QMS often lacks effective operational integration. Insufficient operational integration can result in redundant or outdated procedures that are not aligned with current quality objectives. An ineffective QMS may fail to deliver required quality outcomes, resulting in recurring audit nonconformities, weak linkages to CAPA, and trend data that is not actionable or disconnected from risk management and design control.

The diagram below illustrates core subsystems of a quality management system, including document control, training, CAPA, deviation/nonconformance, audit and inspection, risk management, change management, and more.

What Makes an Effective Quality Management System?

An effective QMS is a risk-based, process-driven framework that integrates customer and regulatory requirements with measurable quality outcomes across the entire product lifecycle. It ensures sustained process control, minimizes quality-related risks, and drives continuous organizational improvement to consistently meet or exceed customer expectations.

A well-functioning QMS demonstrates process control, effectiveness, and traceable, continuous improvement through objective, data-driven quality metrics. It consistently translates quality objectives into measurable results. This includes reduced nonconformance rates, timely and effective CAPA closure rates, successful audit performance, and improved customer satisfaction.

The key qualities of an effective QMS are listed below.

- Leadership Ownership: Quality is a cross-functional responsibility led by executive management. Management must actively engage in setting quality policy, reviewing performance, and allocating adequate resources.

- Easy to Implement and Work With: Procedures, templates, and workflows must be streamlined and integrated into day-to-day operations to minimize administrative burden and promote adoption by all personnel.

- Process-Based Architecture: A Quality Management System should follow a structured process-based framework such as Plan–Do–Check–Act (PDCA), ensuring all processes are clearly defined, interconnected, and traceable. This allows organizations to link inputs (like customer requirements), outputs (such as products or services), and feedback loops (including customer or field data). A process-based architecture supports consistency, accountability, and continuous improvement.

- Risk-Based Thinking: Risk-based thinking should be embedded throughout the QMS to guide decisions and prioritize resources. Risk-based thinking considers the likelihood and potential impact of risks to product quality, regulatory compliance, or customer satisfaction. Risk assessments should inform activities such as design planning, supplier management, operations, and post-market surveillance, among others.

- Data-Driven Decision-Making: An effective QMS must enable the collection, analysis, and use of quality data for informed decision-making. This includes trend analysis, predictive risk indicators, and effective CAPA prioritization. Metrics must be traceable, actionable, and auditable.

- Employee Empowerment: Employees are trained, qualified, and encouraged to identify quality issues, propose improvements, and participate in audits and reviews.

- Customer-Focused Metrics: Quality performance is monitored using KPIs such as complaint trends, product returns, service response times, and satisfaction scores, ensuring alignment with product safety and performance claims.

- Continuous-Improvement Culture: A good QMS supports a culture where internal audits, management reviews, and nonconformity investigations drive CAPAs (where needed), process changes, and training updates. This ensures quality system maturity and continuous improvement over time.

What Is a Quality Management System Assessment?

A quality management system assessment is a formal evaluation of the structure, processes, and performance of an organization’s quality system. QMS assessments determine how effectively it meets internal objectives and external requirements.

A QMS assessment verifies whether the system is functioning as intended, identifies areas for improvement, and ensures alignment with applicable standards or requirements. Requirements include ISO 9001, ISO 13485, Good Manufacturing Practices (GMP), or industry-specific regulations. The assessment also involves reviewing documentation, processes, records, and metrics to assess conformance, effectiveness, and the maturity of the system.

The different types of QMS assessments are listed below.

- Internal Audits: Systematic, independent evaluations conducted by the organization to verify adherence to internal procedures, policies, and regulatory requirements. Internal audits identify process gaps, nonconformities, and improvement opportunities, helping prepare for external inspections and fostering continuous improvement.

- External Audits: Performed by third parties, such as certification bodies or regulatory authorities, to assess compliance with applicable standards and regulations. These include ISO certification audits or inspections by agencies like the FDA or EMA. These inspections can result in observations, warning letters, or enforcement actions if gaps are found.

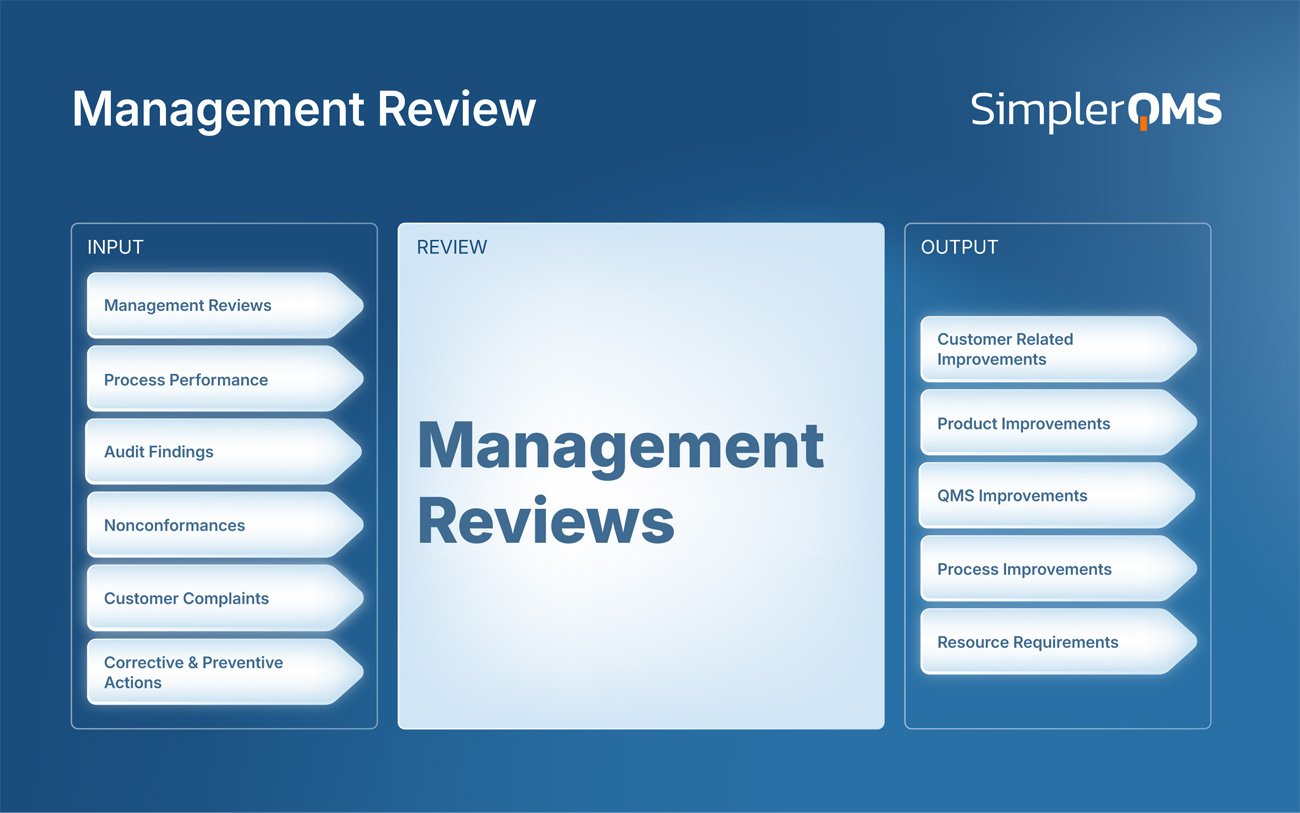

- Management Reviews: Formal evaluations conducted by top management to assess the suitability, adequacy, and effectiveness of the QMS. These reviews examine quality objectives, performance trends, audit results, CAPA status, customer feedback, and improvement opportunities.

- Process Assessments: Focused evaluations of specific quality-critical processes (e.g., CAPA, change control, supplier management) to measure process efficiency, effectiveness, and compliance.

- Supplier Quality Assessments: Reviews or audits of external suppliers to evaluate their capability and performance in meeting specified quality and regulatory requirements. Supplier quality assessments are typically risk-based and are critical for supply chain control.

- Gap Assessments / Readiness Reviews: Performed internally to identify discrepancies between the current state of the QMS and the requirements of a target standard or regulation. These assessments help prepare for audits, certifications, or regulatory submissions.

- Performance-Based QMS Evaluations: Assessments based on key quality performance indicators (KPIs), audit trends, nonconformance data, and risk metrics. These evaluations help quantify QMS effectiveness and support strategic decision-making.

How to Measure the Effectiveness of the Quality Management System?

To measure effectiveness, a QMS must be evaluated both at the system-wide and process-specific levels using objective, risk-based quality metrics. An effective QMS ensures compliance, controls process variability, mitigates risks, and supports continuous improvement.

QMS evaluation should use a closed-loop approach where data is continuously captured and analyzed through the quality system. The effectiveness of a QMS is evaluated using multiple mechanisms, including audits, CAPA activities, post-market surveillance, and ongoing monitoring, measurement, and data analysis.

Key ways to measure the effectiveness of a QMS are listed below.

- Internal & External Audit Results: Audit findings show if QMS processes conform to internal procedures, applicable standards, and regulatory requirements. Fewer, low-risk findings and timely resolutions demonstrate effective internal controls. Repeat or systemic issues indicate gaps in QMS effectiveness.

- Non-Conformance Rates: Trend analysis of nonconformances reveals failure points in process control and system effectiveness. High defect rates or recurring deviations often indicate inadequate process validation, insufficient training, or ineffective risk controls. Monitoring these trends supports early intervention and continuous improvement across the organization.

- Process Capability Indices (Cp, Cpk, Ppk): Cp (Process Capability Index), Cpk (Capability Index adjusted for process centering), and Ppk (Process Performance Index) are statistical metrics used to evaluate whether a process consistently operates within specification limits. These indices are critical for demonstrating validated state, manufacturing control, and long-term process capability in regulated environments.

- Process KPIs & Yield: KPIs assess whether critical quality processes achieve defined outcomes. Yield quantifies the percentage of conforming product, both reflecting operational effectiveness.

- Corrective and Preventive Action (CAPA), CAPA Closure Time and Effectiveness: Effective CAPA systems are measured by the timely resolution of issues, backed by thorough root cause analysis and verification of effectiveness. Delays in closure may signal inadequate resourcing, poor problem-solving practices, or weak accountability. Monitoring CAPA cycle times helps ensure issues are not only addressed, but prevented from recurring.

- Customer Satisfaction Metrics: Indicators such as Net Promoter Score (NPS), product return rate, and complaint trends provide external feedback on device performance, reliability, and perceived quality.

- Supplier Quality Performance: Supplier performance should be evaluated using risk-based metrics aligned with their classification and criticality to operations. Parts-per-million defect rates and delivery timeliness. High rates of incoming defects or missed delivery targets can signal weak supplier oversight and pose risks to product or service quality. Ongoing monitoring supports proactive supplier management and supply chain stability.

- Cost of Quality: Cost of quality analysis segments expenditures into prevention, appraisal, and failure costs, helping quantify the financial impact of poor quality. A shift toward higher prevention/appraisal investment and lower failure costs is indicative of a more mature and effective QMS.

- Risk Register Status & Mitigation Effectiveness: Risk register status assesses how proactively risks are identified, assessed, prioritized, and controlled. This includes verification of residual risk acceptability and effectiveness of mitigation measures.

- Training Effectiveness & Employee Competency Audits: Training effectiveness confirms that personnel performing QMS-related tasks are adequately trained and competent. Training effectiveness is supported by documented competency assessments and must be verified periodically during audits.

- Change-Control Cycle Time & First-Pass Approval Rate: Measures the efficiency and quality of change control processes by tracking the speed of change implementation and the percentage of changes approved without rework.

- Management Review Actions Closure: Tracks the on-time completion of action items from management review meetings, demonstrating executive oversight and commitment to continuous improvement and compliance.

- Document Control Metrics (e.g., Revision Turnaround, Obsolete Docs): Tracks how efficiently quality-critical documents are updated, approved, distributed, and removed when obsolete.

- Continuous-Improvement Projects Completed (e.g., Kaizen, Six Sigma): Tracks the completion and impact of formal improvement initiatives aimed at reducing variation, improving quality, and regulatory readiness.

- Regulatory / Certification Findings & Surveillance Outcomes: Results of inspections and audits by regulatory bodies, Notified Bodies, or third-party certifiers indicate the QMS’s ability to maintain ongoing compliance.

- Benchmarking Against Industry or Standard Benchmarks: Compares QMS performance metrics against industry best practices or standard benchmarks to identify gaps and prioritize improvement opportunities.

Internal & External Audit Results

Internal audits help organizations assess compliance with documented procedures and identify process gaps. Internal audits also serve as a proactive tool to prepare teams for external audits. External audits are conducted by third-party bodies to assess compliance with relevant standards, regulations, or contractual requirements.

Together, internal and external audit results serve as a key system-level metric for evaluating the overall effectiveness of the QMS. These results verify conformance, uncover process weaknesses, and highlight opportunities for improvement.

Organizations should track the number, severity, and recurrence of audit findings over time. A consistent reduction in major non-conformities typically reflects improved process control, more effective CAPAs, and increased QMS maturity.

Non-Conformance Rates

Nonconformance rates measure how frequently processes or outputs fail to meet specified requirements. This includes product defects, process deviations, procedural errors, or customer complaints. These rates indicate the effectiveness of individual QMS processes and the controls in place to prevent quality issues.

Tracking nonconformance rates supports trend analysis and early detection of recurring or systemic issues. For example, an increase in nonconformances during production may signal poor equipment calibration, ineffective process controls, or insufficient training.

Process Capability Indices (Cp, Cpk, Ppk)

Process capability indices, Cp (Process Capability), Cpk (Process Capability Index accounting for centering), and Ppk (Process Performance Index over time) quantitatively assess how consistently a process produces output within defined specification limits.

Cp, Cpk, and Ppk are process-level metrics central to statistical process control (SPC) and are used to verify the adequacy of process design, robustness, and long-term control.

Capability indices are essential for demonstrating ongoing manufacturing consistency and form a key part of Continued Process Verification (CPV), as required by GMP guidelines and ISO 13485:2016 Clause 7.5.6. Regulators often expect capability studies during initial and ongoing process validation to confirm process predictability and support data-driven quality decisions.

Key Process Performance Indicators (KPIs) & Yield

KPIs and process yield measure how well critical quality processes are performing against set quality objectives. While yield specifically reflects the percentage of conforming output, process KPIs provide a broader view of QMS process effectiveness, including efficiency, accuracy, and consistency.

The purpose of monitoring KPIs and yield is to provide early warning signals of potential issues and maintain consistent process output.

Organizations use quality KPIs such as cycle time, error/rework rate, process uptime, or output yield to manage and improve operational control. For instance, low yield in a packaging process may require an investigation into materials or equipment performance. Monitoring KPIs supports proactive quality assurance and drives data-based decision-making.

Corrective- and Preventive-Action (CAPA) Closure Time and Effectiveness

CAPA closure time measures how quickly an organization responds to quality issues by investigating root causes and implementing corrective or preventive actions. CAPA effectiveness must also be evaluated to ensure that actions taken successfully eliminate the root cause and prevent recurrence.

CAPA closure time and effectiveness are system-level and cross-functional metrics that reflect the organization’s ability to manage quality issues, respond to risk, and drive continuous improvement.

Organizations should track average CAPA closure time and monitor overdue actions. For example, delayed CAPA resolutions may reveal bottlenecks in investigation or resource constraints. Ineffective CAPAs often point to poor root cause analysis or inadequate corrective actions.

Customer Satisfaction Metrics

Customer satisfaction metrics like the NPS, product return rates, and complaint trends reflect how well the QMS aligns with user expectations.

A Customer satisfaction metric is a system-level metric that reflects overall effectiveness in delivering quality outcomes.

Customer satisfaction metrics help organizations validate whether internal quality performance translates to customer satisfaction. For example, increasing complaints despite stable internal defect rates could indicate issues in product usability.

Supplier Quality Performance

Supplier performance metrics, such as incoming defect rates (parts per million) and on-time delivery, assess the quality and reliability of externally sourced materials and components.

Supplier quality performance is a process-level evaluation that supports effective supply chain control. The goal is to ensure suppliers consistently meet predefined quality and delivery expectations.

Organizations typically maintain supplier scorecards and conduct periodic reviews or audits to ensure fulfillment of supplier quality requirements. For example, repeated delivery delays or high defect rates from a critical supplier may compromise production timelines and overall product quality.

Cost of Quality

The cost of quality categorizes spending into prevention, appraisal, internal failure, and external failure costs.

Cost of quality is a system-level metric that shows the financial impact of quality-related activities and failures.

Cost of quality enables strategic resource allocation by determining whether increased investment in preventive measures would be more effective than addressing issues after they occur.

Tracking the cost of quality over time helps reduce waste and improve product quality. For example, high external failure costs such as warranty claims or product recalls signal insufficient process control or delayed detection of critical product quality issues.

Risk Register Status & Mitigation Effectiveness

The risk register is a controlled document that logs identified quality and compliance risks, their assessed severity, mitigation strategies, ownership, and residual risk status.

This system-level metric is critical for demonstrating the effective implementation of risk-based thinking as required by ISO 9001:2015 Clause 6.1 and ISO 14971 for medical devices.

The risk register must be routinely reviewed during management reviews and updated as new risks emerge or existing ones evolve. Evaluating open risks, overdue actions, and repeated high residual risk ratings provides insight into whether current mitigation efforts are effective or if CAPAs and controls need to be strengthened.

Maintaining traceability between risks and associated processes, such as supplier controls, design inputs, and post-market surveillance, is essential to ensure that systemic risks are not siloed.

Failure to address persistent high-severity risks may constitute a deficiency during audits or inspections, potentially impacting product safety, efficacy, performance, or regulatory compliance.

Training Effectiveness & Employee Competency Audits

Training effectiveness evaluates whether employees are gaining and applying the required knowledge and skills, while competency audits verify actual job performance and capability.

Training effectiveness and employee competency audits are system-level metrics that support sustained quality by ensuring a qualified and capable workforce. The aim is to link training investments to improved quality outcomes.

Organizations assess training effectiveness through knowledge testing, performance observation, and post-training error tracking. For example, recurring operator errors following procedural training may suggest ineffective training content or poor delivery.

Change-Control Cycle Time & First-Pass Approval Rate

Change-control metrics evaluate the timeliness and quality of managing proposed modifications to product design, manufacturing processes, equipment, and controlled documents.

Change-control cycle time is a cross-functional, system-level indicator reflecting both operational effectiveness and adherence to regulatory requirements, particularly regarding traceability and documented justification of changes.

Measuring the average cycle time and first-pass approval rate helps organizations assess whether change controls are properly scoped, risk-assessed, and executed in accordance with internal procedures.

A low first-pass rate may indicate deficiencies in impact assessments, poor stakeholder engagement, or inadequate documentation. These metrics ensure that only validated, approved changes are implemented, thereby minimizing compliance risk.

Management Review Actions Closure

Timely closure of action items from management reviews demonstrates an organization’s commitment to strategic quality initiatives and continuous improvement.

Tracking the closure rates of management review actions is a system-level metric. It confirms leadership engagement and follow-through. Its strategic purpose is to ensure that insights and outputs from management reviews lead to measurable quality improvements.

Organizations should log all management review decisions, assign clear ownership, and monitor closure status. For example, repeated delays in closing out critical actions may indicate prioritization issues or resource constraints.

The diagram below shows key inputs to management review, such as audit findings, nonconformities, customer feedback, and process performance, leading to decisions on corrective actions, improvements, resource allocation, and quality objectives.

Document Control Metrics

Document control metrics track the efficiency of creating, updating, distributing, and retiring controlled documents.

Document control metrics are process-level metrics that ensure operational effectiveness and regulatory compliance. The strategic aim is to prevent errors due to outdated or unclear documentation.

Organizations use metrics such as revision cycle time and the number of obsolete documents in circulation. For example, excessive delays in document revision can postpone necessary updates to critical procedures, potentially impacting product quality or compliance. Document control is a core requirement of any quality management system and is required by standards such as ISO 9001 and ISO 13485.

Continuous Improvement Projects Completed

Continuous Quality Improvement (CQI) is an ongoing effort to improve processes, products, or services through systematic, data-driven methodologies such as Kaizen and Six Sigma. The completion of quality improvement initiatives such as Kaizen events or Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) projects is an indicator of an effective, data-driven quality culture.

Kaizen is a continuous improvement methodology focused on small, incremental changes in processes to improve efficiency, quality, and employee engagement.

Six Sigma is a data-driven methodology focused on reducing process variation and defects. Six sigma uses structured problem-solving frameworks like DMAIC to improve product and process quality.

Both Kaizen and Six Sigma are examples of continuous improvement methodologies that demonstrate how consistently continuous improvement is integrated into the QMS. This aligns with regulatory expectations for quality management, including ISO 9001:2015 Clause 10.3, and ISO 13485:2016 Clause 8.5.1. Metrics such as the number of completed Kaizen or Six Sigma projects, or the measurable impact of these initiatives, for example, defect reduction, serve as system-level indicators of CQI maturity.

Continuous quality improvement initiatives support the reduction of process variation, improvement of product quality, and mitigation of recurring nonconformities.

Organizations can evaluate the impact of CQI projects based on metrics such as process yield improvements, cost-of-quality savings, and recurrence rate of previously identified issues. For example, a Six Sigma project targeting CAPA cycle time could lead to faster issue resolution and improved compliance.

Regulatory / Certification Findings

Regulatory or certification findings evaluate the frequency, severity, and closure status of nonconformities identified during regulatory inspections (FDA, EMA) or certification audits (ISO 13485, ISO 9001).

Regulatory or certification findings are system-level indicators of QMS maturity, compliance status, and an organization’s ability to maintain ongoing inspection readiness. The strategic purpose is to assess conformity with applicable regulations and standards, including EU MDR 2017/745, EU IVDR 2017/746, and FDA 21 CFR Part 820, and to support proactive compliance management.

Organizations should document all audit findings (minor, major, critical), assign CAPAs, link findings to risk assessments, and track closure timelines in accordance with internal SOPs and audit response procedures. A trend of repeat observations or extended CAPA timelines may signal systemic QMS weaknesses.

Benchmarking Against Industry or Standard Targets

Benchmarking is a structured method for comparing internal QMS performance metrics against industry standards or best practices.

As a cross-functional indicator, benchmarking against industry standards supports management review inputs, strategic planning, and prioritization of improvement initiatives.

Standards and regulations require timely and effective quality processes. For example, ISO 13485 and FDA regulations expect CAPAs to be implemented in proportion to the level of risk and verified for effectiveness. To meet these expectations, organizations often adopt performance metrics (e.g., CAPA closure within 30-60 days or a ≤100 PPM defect rate). Such measurable benchmarks support the timely closure of non-conformities and drive continuous improvement.

Benchmarking against industry standards helps organizations identify underperformance and mitigate compliance risk. For example, persistent deviation from industry norms on first-pass yield or CAPA closure rate may necessitate a formal management review escalation. It can also initiate cross-functional corrective action planning.

What Are the Ways to Improve a Quality Management System?

Improving a quality management system involves taking deliberate actions that improve its structure, performance, and alignment with business and regulatory goals. These improvements strengthen compliance, reduce risk, and create a culture of continuous quality.

The different ways to improve a QMS are listed below.

- Strengthen Leadership Commitment: Active leadership support is essential for a high-performing QMS. Leaders should define quality objectives, allocate necessary resources, and participate in management reviews to reinforce quality as a strategic priority across the organization.

- Engage and Train Employees: A quality-driven culture depends on knowledgeable and empowered employees. Providing regular training, verifying competency, and involving employees in improvement initiatives helps reduce errors and increase ownership of quality outcomes.

- Standardize and Document Key Processes: Documenting processes ensures consistency and clarity in execution. Standard operating procedures (SOPs), work instructions, and forms provide a clear roadmap for teams and reduce variability across departments or locations.

- Track Data-Driven KPIs for Decision-Making: Quality performance should be monitored using measurable, data-based metrics such as defect rates, CAPA closure times, and audit findings. Monitoring KPIs supports informed decision-making and enables early identification of performance gaps.

- Apply Continuous-Improvement Cycles: Using structured improvement models like Plan-Do-Check-Act (PDCA) or Kaizen fosters incremental, sustainable improvements. These quality cycles support systematic problem-solving, implement solutions, and verify effectiveness over time.

- Use Risk-Based Thinking to Prioritize Actions: Applying risk-based thinking ensures that resources are focused on areas with the highest potential impact on product quality, customer satisfaction, or compliance.

- Run Regular Internal Audits and Management Reviews: Internal audits and management reviews are key mechanisms for evaluating the health of the QMS. They help detect process weaknesses, verify action completion, and ensure alignment with quality objectives.

- Digitize With QMS Software for Improved Efficiency: Transitioning to an electronic eQMS streamlines processes like document control, CAPA management, and training tracking. Digital systems improve traceability, reduce manual errors, and improve audit readiness through automation and centralized access.

The eQMS business case template below can be used to justify investment in quality management software to stakeholders. This template helps teams create a clear, structured business case and communicate the potential ROI, compliance benefits, and efficiency gains of transitioning to a digital QMS platform.

How QMS Software Helps Establish and Maintain an Effective QMS?

QMS software is a validated digital platform that integrates all quality management activities, such as document control, training, CAPA, audits, and change control, into a centralized system. QMS software provides end-to-end visibility, control, and traceability across every QMS process, ensuring oversight and supporting regulatory compliance.

An effective quality management system combines well-defined procedures and their consistent, efficient implementation in compliance with applicable regulations, standards, or guidelines such as ISO 9001, ISO 13485, or ICH Q10. QMS software underpins this by creating a closed-loop, data-driven quality ecosystem that helps reduce manual errors, establishes procedural controls, and ensures timely escalations, reviews, and approvals.

The key ways in which QMS software supports an effective quality management system are listed below.

- Centralized Document Control & Versioning: Ensures documents like procedures, forms, and records are version-controlled, securely stored, and easy to retrieve. This eliminates uncontrolled copies and links documents to related activities such as training or change management.

- Automated Workflows: Replaces manual steps with automated routing for tasks such as CAPA, change control, and training. This improves process consistency, accountability, and on-time completion of quality activities.

- Dashboards & Analytics: Provides real-time visibility into key quality metrics and trends. Teams can quickly identify issues such as overdue tasks or rising nonconformances and make data-driven decisions.

- Regulatory Compliance & Audit Readiness: Supports compliance through secure records, traceable actions, and electronic review and approval. These features simplify audit preparation and improve response accuracy during inspections.

- Risk-Based Decision Support: Integrates risk assessments into core quality processes like supplier management and change control. Tools such as scoring and tracking help prioritize actions and ensure risks are addressed proactively.

- Closed-Loop Quality Event Management: Links quality events like complaints, nonconformances, and CAPAs to ensure effective resolution and long-term prevention. This structured approach strengthens root cause analysis and continuous improvement.

- Integrated Training Management: Connects training directly to roles and controlled documents. When a document changes, retraining is automatically triggered, and employee qualification can be verified and tracked.

- Supplier Quality Oversight: Enables centralized monitoring of supplier qualifications, performance, and corrective actions. This improves supply chain control and reduces supplier quality-related disruptions.

- Validation and Change Control: Manages system updates and configuration changes in a controlled and documented manner. This ensures reliability and traceability of software changes, especially in regulated environments.

SimplerQMS provides a QMS software purpose-built for companies operating in regulated environments. SimplerQMS offers an intuitive interface that streamlines the management of audits, inspections, and quality processes.

The SimplerQMS platform supports a wide range of interconnected quality processes, including audit management, CAPA, nonconformance handling, change control, document management, training, supplier management, and complaint handling within a single validated system. It helps ensure efficient management of quality management processes, supporting compliance with standards and regulations, including ISO 13485:2016, FDA 21 CFR Part 820, 21 CFR Part 11, EU MDR 2017/745, and IVDR 2017/746, EU GMP, and ICH Q10. SimplerQMS is a fully validated software in accordance with GAMP 5, significantly reducing the validation burden, and is also compliant with software validation requirements as per ISO 13485 and FDA 21 CFR Part 820.

With SimplerQMS, organizations can reduce the administrative burden of compliance, prevent audit deficiencies, and maintain an effective and audit-ready QMS.